Process validation performs an important job in high-quality assurance by giving assurance that a producing process is below Command and capable of constantly creating products that meet customer needs.

Technological know-how is advancing at a unprecedented fee. Industries are benefiting from automation and AI…

one. Future Validation: This refers to validation actions completed before commencing plan manufacturing. You ought to make this happen prior to deciding to manufacture the product or service with a new method or in a completely new manufacturing facility.

Process validation can be described since the documented evidence that establishes a higher diploma of assurance that a selected process will constantly create a product that fulfills its predetermined specs and top quality attributes.

The process qualification stage is significant in creating self-assurance within the process's ability to constantly generate high-good quality items. It provides proof that the process is less than Regulate and effective at Conference the specified outcomes.

Constant process verification analyses important process parameters and important quality attributes in real time to confirm creation stays inside suitable concentrations and fulfills standards set by ICH Q8, Pharmaceutical Excellent Systems, and Excellent producing observe.

5.Summarize Vital Results: Provide a crystal clear summary of the leading achievements and difficulties, specializing in the most crucial components of the process validation and verification.

It is additionally regarded as the foundational variety of validation mainly because it would be the place to begin for just about any solution that may be introduced below new circumstances.

In summary, process validation is an important part of high quality assurance while in the manufacturing process validation protocol template industry. It ensures that producing processes are effective at continuously producing superior-good quality products that meet client requirements and regulatory criteria.

Prior to deciding to go, right here is an additional statistic: eighty% of our customers originate from referrals. If you wish to grow to be considered one of our joyful consumers, Contact Us and Permit’s start a conversation.

To remain compliant, you must scientifically show and doc that the cleaning approaches more info regularly get rid of residues under the set up acceptance standards.

Ongoing process checking can be a important requirement outlined because of the EMA. This includes the standard monitoring and Assessment of process details to make certain that the process remains in the state of Command.

The info collected in the course of this stage provides important insights into your process's effectiveness eventually. It allows for the identification of any developments or deviations from the validated point out, enabling well timed corrective actions for being taken.

5. Regularly overview and update stakeholders on crucial findings. Sound documentation turns validation efforts into worthwhile references for continual advancement.

Michael Bower Then & Now!

Michael Bower Then & Now! Brandy Then & Now!

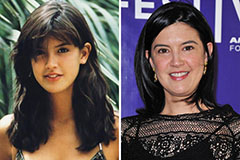

Brandy Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!